Mechanical & Electrical Design

Samwell has been serving the engineering industry for nearly two decades, catering to a wide range of project requirements for esteemed companies both domestically and internationally. As a market leader in our areas of expertise, we offer comprehensive design, compliance, and management services to our valued customers. We prioritize accuracy, reliability, and efficiency, ensuring that our clients receive the highest level of satisfaction.

Furthermore, our design team provides a wide range of services in mechanical structure design, tooling/mould development, computer-aided analysis and product structure / electrical validation, special expertise in the design for the ruggedized product for which features as extreme temperatures, water, dirt and shock resistance. From prototype to delivery, Samwell can be your best choice.

Over mould Injection

Over moulding is a process where a melt processible elastomer like a TPE is moulded directly onto a rigid component, known as the insert or substrate.

By far the process most often used for over moulding TPEs onto rigid plastics, insert moulding requires the least hardware reconfiguration and investment. In this design the rigid insert, moulded separately, is placed into the tool and the TPE is injected onto it.

IMD (In-mould Decoration)

The advantages of IMD are:

Cost saving: Injection moulding and decoration in one operation.

Upgrade of Decoration: Decoration on curved and uneven surface is possible. Gloss, Matt, Texture, Metallic effect can be generated. No warping caused by secondary Operation.

IMD allows you to achieve different colors, effects, and textures that are complete when the part comes out of the mould. When any of these factors need to change, there is no need to re-tool or change resin color. Just simply change the film and you can change the appearance or texture dramatically.

Twin-Shot Injection

This process requires two injection moulding machines and an expensive, complex tool, with several gates and activated slides. The rigid material is injected first, then the mould is indexed to the TPE injection machine where the rubber is injected onto the rigidsubstrate. Since the hot substrate is usually in a semi-solid, gel phase at this point, melt and chemical bonding is generally better than can be achieved by insert moulding over an unheated substrate. These moulds can be designed with undercuts and overhangs in the rigid part to ensure that a stable mechanical bond is attained.

Plastic Injection

Samwell plastic injection mold is able to meet the precise dimension, low shrinkage, high impact strength, high flexible and yield tensile of your products.

Metal Injection

Metal Injection Moulding (MIM) is a near shape process, which is used to produce large quantity of small parts with complex shape and high precision . The advantages of metal injection are :

Magnesium & Alloy Die Casting

We offer the complete process from mould making, die-casting, reworking, finishing, and assembling to packing and shipping. With over 20 years experience on hardware production has earned us a reputable reliability and competitiveness on this global market.

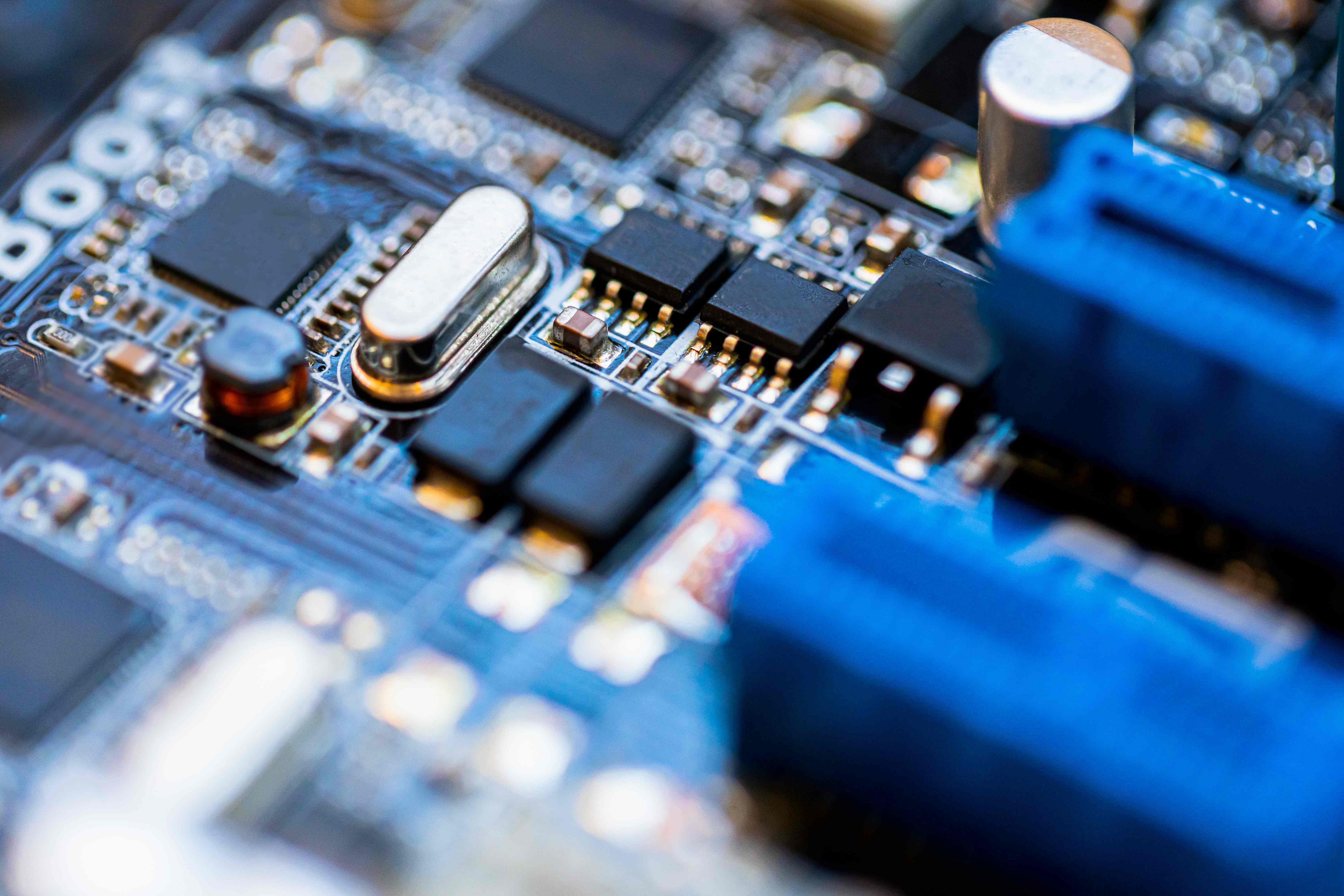

PCB Assembly

We offer complete solution for PCB Assembly using the latest technology in design, manufacturing and testing. From single to multi-layer, our expertise encompasses ranging from prototype assembly, quick-turn assembly to PCBA. We offers the following PCB Assembly solutions:

.jpg)